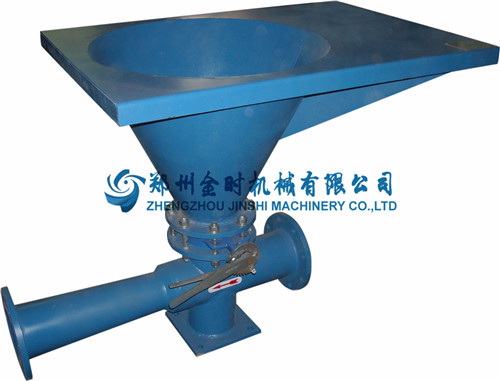

JSL seriesJet Mixer, an commonly used equipment in mixing fluid,is an important part of drilling fluid solid control system.When well blowout occurs,it can be used to mix large amount of weighted materials even in drilling fluid within little time.

The drilling fluid flow into the jet pump with certain pressure,in the jet pump fluid spouts out from jet nozzle first, then flows into shear pipe through mixing chamber. Materials will be added from hopper to mixing hopper, and move into shear pipe with the flow. During this process, they are dispersed and mixed. The mixture will enter into drilling fluid tank when flows out of the shear pipe.

The shear pipe is hollow and it can expand gradually based on certain curved surface. It is mainly used to enlarge shearing force inside the pipe to disperse the material further and increase the mixture pressure head, this will make it easy to enter into circulating tank.

Bernoulli effect is adopted in shear pipe which is flow rate is rapid with low pressure, and slow with high pressure. Pressure is low in the chamber when fluid spouts out in high speed from the jet nozzle; when fluid enters into the shear pipe, its section is enlarged and flow rate decreased so the pressure rises.

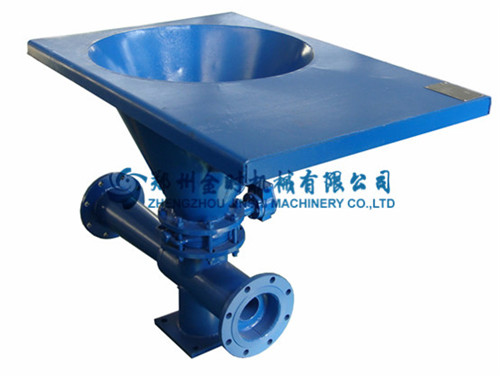

Model | JSL-100 | JSL-150 |

Discharge capacity | 100 m3/h | 200 m3/h |

Inlet pressure | 0.25~0.6MPa | 0.25~0.6 MPa |

Outlet pressure | 0.1~0.3MPa | 0.1~0.3 MPa |

Inlet diameter | 4″(3″) | 6″ |

Outlet diameter | 4″ | 6″ |

Weight | 100 kg | 130 kg |

Overall dimension | 600×400×720mm | 1375×750×950mm |